Different Types of Concrete Repair

Once the cause and significance of concrete damage have been determined, a repair method can be selected. Concrete replacement is a common choice for major defects such as honeycombbing. Replacement concrete should have a low w/c to minimize shrinkage cracking.

Test the concrete with a hammer to determine whether it carries a hard ring and is sound. For more information, you can visit Concrete Repair Colorado Springs to proceed.

Concrete cracks can lead to a loss of strength and structural integrity. Whether the cracks are due to drying shrinkage, thermal expansion, or simply because of a design or construction error, if they are structurally significant, it may be necessary to repair them to ensure that a building or structure can continue to carry the load intended for it.

The most common method of repairing concrete cracks is routing and sealing. This involves enlarging the crack and filling it with silicones, epoxy, or urethane sealants. This type of repair is ideal for both dormant and active concrete cracks. To avoid a potential problem with water ingress, it is important to V-cut the crack before applying the sealant. This will allow the adhesive to expand and contract as the concrete moves and will help prolong the life of the sealant.

A good bond is essential when repairing concrete cracks, especially between the existing concrete and the revised material. The quality of the bond is determined by the ability of the repair material to adhere to the existing surface. In addition, the bond must be strong enough to withstand the expected stresses and movements of the concrete.

Many concrete repair materials need to be more suitable for vertical or overhead surfaces due to their poor adhesion to the existing surface. However, some products designed specifically for these applications offer unsurpassed durability in harsh environments.

When using a conventional concrete placement method, it is imperative to use a low w/c and a high percentage of coarse aggregate to minimize cracking during curing. It is also important to use an appropriate aggregate to reduce the permeability of the repair. This will prevent contaminants from entering the concrete and causing further damage.

Epoxy injection is a non-invasive, thorough, and permanent repair process that will restore structural concrete elements such as foundations, slabs, and walls to their original strength and stability. It is also a good method for sealing cracks in structures and homes. However, it is important to determine the cause of the cracking before proceeding with the epoxy injection. This can be done using non-destructive testing (NDT) methods such as seismic, ultrasonic, and sonic pulse velocity.

Before injecting the epoxy, cleaning out the crack with water or high-pressure air is a good idea. A wire brush may be used to clear out any dirt or debris. The crack must be dry as well for the epoxy to adhere properly.

Once the crack is cleaned, the injection ports are installed in a pattern spanning the entire length. The injection ports are then capped with paste-over epoxy to seal the tops. After the ports are limited, the crack is injected with a low-viscosity epoxy or polyurethane to fill and bond the crack.

It is recommended to start with the lowest port and inject epoxy until it shows up in the port above it. This ensures that all the crack is injected and is not blocked by the surface crack. This is a common mistake that can lead to leaking cracks.

The next step is to cap off the lowest and above ports. This will prevent leaking into the structures. The epoxy injection should be continued until the crack is filled. Once the infusion is complete, wait 24 hours before removing the ports.

Once the injection has cured, using a heat gun to soften the epoxy and make removing it easier is a good idea. A chisel or scraper may be used to remove the epoxy; wearing a respirator is a good idea. Epoxy is a toxic substance and should not be allowed to reach the skin or eyes.

If your concrete basement or foundation cracks need to be repaired, there are many different products and methods that you can use. Some of these are more effective than others in stopping water, providing structural support, or improving the appearance of the concrete. However, it’s important to understand the differences between these products to select the best solution for your specific situation.

Hydraulic cement is a common repair product that stops leaks in concrete and masonry structures. It is a quick-setting material that can seal running water or leaks from active cracks in the most demanding situations. It can be mixed in a powder form and applied to the surface of the leak quickly. It sets rapidly (normally in three minutes) once mixed with water. The temperature of the water or admixture will control the setting time. It can be used above or below grade and is noncorrosive and waterproof.

Typically, hydraulic cement is composed of anhydrous calcium silicate hydrates. It contains alum, deletes, and delete for strength and brown millerite for hydration. These components help to make it resistant to shrinkage and abrasion. It’s also an excellent choice for underwater applications, as it won’t wash away as easily as regular concrete.

This product is inexpensive, so it’s affordable for repairing small leaks and other minor cracks in concrete structures. However, it is not an appropriate repair solution for structural or widening cracks because it does not provide significant tensile strength. This type of repair patch is often applied to the surface of cracks to prevent water penetration or pest intrusion, but it does not address the root causes of the cracks. It may be used on interior or exterior surfaces. Still, it is not a permanent repair for concrete – especially in a basement – and should not be exposed to continuous moisture.

It’s also important to note that hydraulic cement is very weak, so it is always combined with other materials, such as sand and aggregate, to create concrete. As such, it is prone to cracking and unsuitable for filling wide structural cracks in a basement or foundation wall. It is also a poor solution for cracks that run outside a basement foundation because it will be subjected to pressure from water and lateral forces from the soil. A better permanent solution is installing an exterior urethane waterproofing membrane by a qualified professional.

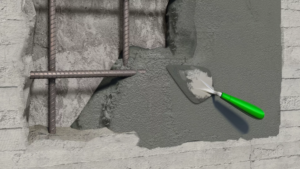

Bonding agents are a crucial step in the concrete repair process. These chemicals can distinguish between a repair that lasts and one that fails, particularly in high-traffic areas or demanding environments. They are designed to increase the adhesion between the existing surface and repair mortar, cement slurry, or poured concrete. Additionally, they can provide corrosion protection to exposed steel reinforcing bars. There are several types of bonding agents on the market, so choosing the right one for your job is important.

The type of bonding agent you need depends on the materials and surfaces you are working with, the application method, and the drying time. Liquid bonding agents are typically mixed with water, sand, and cement to create a slurry that is applied to the surface while it is still sticky. Two-part epoxy bonding agents are similar to construction adhesives and can be mixed directly before application. Powder bonding agents are typically used for larger projects or in areas that require a slower curing process.

Before using any bonding agent, preparing the surface for the application is important. Chiseling the existing concrete surface is often necessary to remove loose or damaged materials and ensure the bonding agent can adhere properly. Brushing or vacuuming the existing surface is also a good idea to remove any dirt and debris interfering with the bonding process.

Once the surface has been prepped, following the manufacturer’s instructions when applying the bonding agent is important. Some products may require that the user roughen the surface before application, while others will cling to smooth surfaces provided they are free of dirt and contaminants.

Some great bonding agents are available on the market, including epoxy, polyurethane, and cementitious. It is important to select the right bonding agent for your project to ensure that it will hold up under the conditions of your repair job. For example, an epoxy bonding agent will provide superior strength and durability, while a polyurethane bonding agent will be more flexible and able to withstand harsh environments.